Grade 201 stainless steel is an austenitic chromium-nickel-manganese stainless alloy.it is a lower-cost alternative by conserving nickel to the conventional Cr-Ni austenitic stainless steels, such as 304 strips. About half of the nickel content of 304 is replaced with alloy additions of manganese and nitrogen. This results in a higher strength than 304. 201 stainless steel strip has relatively lower ductility and formability compared to 301 stainless steel strip.

Grade 201 also has good welding characteristics and low temperature properties.

Because of 201 's relatively high yield strength in the annealed condition, use of 201 is limited.

Type 201 is generally used in the tempered condition particularly for springs and fasteners.

Width:1000mm/1219mm/1240mm/1500mm or as customer's requirements

Thickness:Cold rolled:0.3~3.0mm

Hot rolled:3mm~10mm

Material:and we also other grade,such as 201,202,301,302,303,304,304L,304N1,309S,310S,316,316L,

316Ti,316N,317,317L,321,409L,410,420,430,904L,etc

Grade: 200/300/400 series/904L/duplex stainless steel

Standards:AISI ASTM JIS SUS and GB

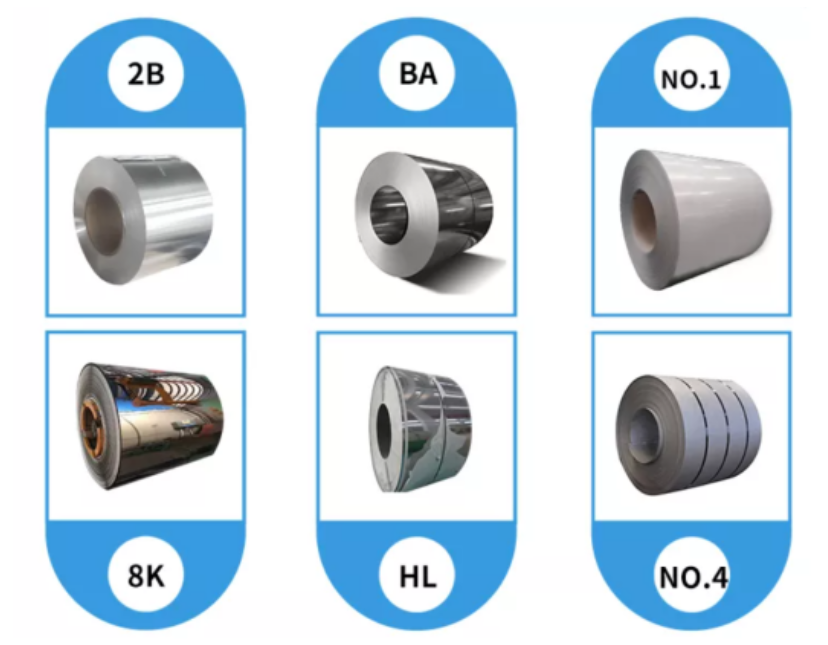

Surface: 2B/NO.1/8K/2D/BA/NO.4/NO.6/NO.8 etc

Surface | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Packaging & Delivery

Packaging Details:

In bundles with seaworthy wooden pallets or as per requirement.

The inner size of container is below:

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM

Delivery Detail:

5-15 working days

Contact: Laura

Phone: +86-18232958738

Tel: +86-18232958738

Email: admin@primeesteel.com

Add: No.14, Jingbao Yiwei Road, Wangqin Village, Beicang Town, Beichen District, Tianjin

We chat